Want to buy or sell something? Check the classifieds

-

The Fedora Lounge is supported in part by commission earning affiliate links sitewide. Please support us by using them. You may learn more here.

Ask a Question, Get An Answer About Outerwear

- Thread starter ABCD

- Start date

Pandemic

One Too Many

- Messages

- 1,512

- Location

- In The Flat Field

Tuck it in or buy shorter t-shirts. You can always tuck the sides in and leave a little hanging over the belt in front of you don’t like the ‘neatly tucked’ look.

- Messages

- 15,563

- Location

- East Central Indiana

I just think it looks very sloppy untucked. However it seems a fad now to wear shirts untucked no matter if they hang well below the jacket.

Pandemic

One Too Many

- Messages

- 1,512

- Location

- In The Flat Field

I’d never tuck a shirt into jeans unless I had a jacket on. Then, I usually do a sloppy tuck - just the sides or just the front behind the belt. And the back.

JurassicUtility

One of the Regulars

- Messages

- 149

My experience with BK was unremarkable in the sense that all went smooth. Placed the order and after 3 months I got my jacket. I did a sort of custom order changing the collar from shawl to the wingman one on a cadet.

I ordered it in Black Liberty (HH). I personally haven’t experienced much wear through in the 2 year and half I’ve had the jacket. Maybe the Liberty Seal has a weaker top coat or maybe different batches have different features. Cuffs for me are pretty standard width wise I wouldn’t want them any tighter.

The only real information impressions or information I've found about Victory and Liberty horsehide on the web has come from this forum - so that leads me to a question I've had for awhile: How do you tell the difference between Liberty and Victory horsehide? My secondhand Duke is presumably regular seal, Victory horsehide, since that is what it was advertised as. However, the main distinguishing feature I've gathered from reading discussions on here is that the finish/topcoat on Liberty horsehide wears off significantly faster. My jacket has been getting some pretty serious wear this winter, but I wouldn't say the finish is particularly hard wearing. I'm including some pictures here to show off the wear/patina on the collar, under the arms, and at the sleeves. Like Mich486 said, I could easily believe there is a lot of batch-to-batch variation with both leather types, so some batches just get finishes that adhere better than others.I have experienced the Liberty wear through on a couple of BK brown jackets. One I still own. I sold a Black Liberty and was always curious is they went through the same process. I don't know much about the company, I see very few of their jackets on the used market.

The Victory horsehide is legendary for its' cost and hence it's rarity. I have seen only a few of the Victory jackets for sale ever.

Two hugely different leathers.

View attachment 302708 View attachment 302709 View attachment 302710 View attachment 302711 View attachment 302712

There's a dearth of information about Victory horsehide online, so I don't have much of a comparison point to say weather this is normal and expected wear for this leather type. The way it is wearing doesn't really bother me - I quite like how its developing actually, but I thought I'd submit the question since I have no way to directly compare the two leather types myself.

It's also an excuse to upload some siiick pictures of that patina.

View attachment 306759

What do yall do about t shirts sticking out from under your jackets?

Is it a bad look?

It seems if I’ve got less than an inch of t shirt sticking out it’s fine, but any longer and it starts to look bad.

The untucked look is pretty old now - I certainly haven't tucked in a shirt or t-shirt since the mid 1980's. Neither have most of the guys I know. But I suspect this is down to taste and age. It probably looks least good if you wear an A2 or cross zip.

damn I like this patina, color fades but leather stays smoothThe only real information impressions or information I've found about Victory and Liberty horsehide on the web has come from this forum - so that leads me to a question I've had for awhile: How do you tell the difference between Liberty and Victory horsehide? My secondhand Duke is presumably regular seal, Victory horsehide, since that is what it was advertised as. However, the main distinguishing feature I've gathered from reading discussions on here is that the finish/topcoat on Liberty horsehide wears off significantly faster. My jacket has been getting some pretty serious wear this winter, but I wouldn't say the finish is particularly hard wearing. I'm including some pictures here to show off the wear/patina on the collar, under the arms, and at the sleeves. Like Mich486 said, I could easily believe there is a lot of batch-to-batch variation with both leather types, so some batches just get finishes that adhere better than others.

There's a dearth of information about Victory horsehide online, so I don't have much of a comparison point to say weather this is normal and expected wear for this leather type. The way it is wearing doesn't really bother me - I quite like how its developing actually, but I thought I'd submit the question since I have no way to directly compare the two leather types myself.

It's also an excuse to upload some siiick pictures of that patina.

View attachment 306759 View attachment 306760 View attachment 306761 View attachment 306762 View attachment 306763 View attachment 306764 View attachment 306765 View attachment 306766 View attachment 306768

I remember the Victory hides had a lot of red tones in them.

https://www.thefedoralounge.com/threads/bill-kelso-duke-in-victory-hh.77584/

https://www.thefedoralounge.com/thr...-a2-victory-horse-dark-seal-aero-18775.74229/

https://www.thefedoralounge.com/threads/bill-kelso-duke-in-victory-hh.77584/

https://www.thefedoralounge.com/thr...-a2-victory-horse-dark-seal-aero-18775.74229/

Last edited:

tmitchell59

I'll Lock Up

- Messages

- 7,865

- Location

- Illinois

I have no way to directly compare the two leather types myself.

That looks like Liberty Horsehide, color, texture, wear. Looks Great to me.

Here is a Victory Duke

https://photos.app.goo.gl/H8EqX9ixASxKccXSA

Here is the Victory Duke and Liberty Monarch A2, Liberty Dodger

https://goo.gl/photos/5YdgYRH71LZsjeWy9

Here are a some for comparison

The untucked look is pretty old now - I certainly haven't tucked in a shirt or t-shirt since the mid 1980's. Neither have most of the guys I know. But I suspect this is down to taste and age. It probably looks least good if you wear an A2 or cross zip.

I don't even tuck my shirt in at official events lol

I think the pulled thread at the seams is also a compromised balance between wanting the top stitching as close as possible to the edge (probably looks better for small stitching like Himel) resulting in pulled seams when thicker hide is used, and vice versa ala Aero's top stitches with huge margin to the edge of any seams. somewhere in the middle is the sweetspot, and probably have to be adjusted for different kind of leather thickness, but they are making so many jackets so they decide a margin a compromise they see most fitting to them and just go with it. I dont think skill is the factor there just different kind of foot (or whatever the name of that ski blade like thing to pin down the material and guide the needle) on the sewing machine, maybe one with 2mm gap to the edge, another with 4mm gap to the edge just my guessing.

some of those feet have bumper to feel the edge of the material, so as long as the person is sober enough to feel it basically guide the stitching at fixed distance to the edge so no super skill needed. probably a skilled person would do it a lot faster, but a complete newbie won't end up with wavy sewing either although probably a lot slower to do the same thing.

I was not talking about the top stitch, but about the first stitch line being made visible beneath the fold.

If you look at this for example you can see the the first line is never visible because they never pull the two parts too much before stitching. (they are using super soft material)

I think that if you use tougher material you have to beat the fold more to flatten it before you top stitch.

If you pull it too tight you reveal the first stitch line.

6:15-6:30 for the shot of what i am talking about:

Edit: when it happens on a single seam it is called "seam grin" and is a tension issue.

Last edited:

ABCD

I'll Lock Up

- Messages

- 7,462

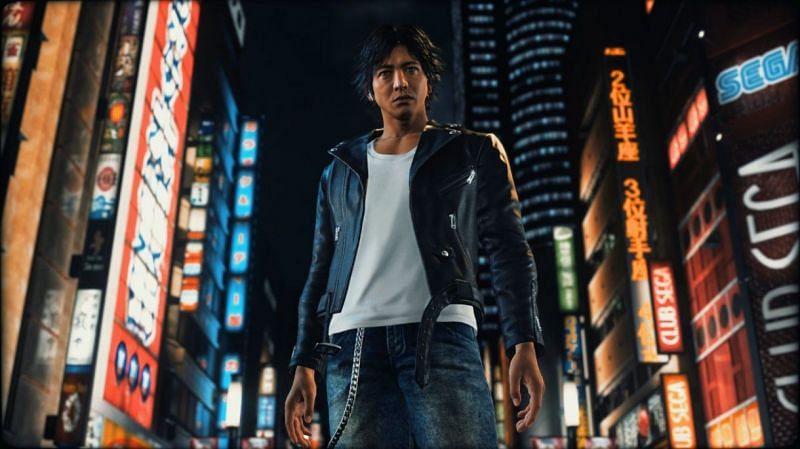

This game was released in December 2018, makes me wonder if he is wearing a leather jacket because it is a trend in Japan. He wears it untucked

I have the feeling that the untucked t-shirt / low rise pants trend in Japan is the reason why brands like FC and Y2 offer all those elongated leather jackets.

I was not talking about the top stitch, but about the first stitch line being made visible beneath the fold.

If you look at this for example you can see the the first line is never visible because they never pull the two parts too much before stitching. (they are using super soft material)

I think that if you use tougher material you have to beat the fold more to flatten it before you top stitch.

If you pull it too tight you reveal the first stitch line.

6:15-6:30 for the shot of what i am talking about:

Edit: when it happens on a single seam it is called "seam grin" and is a tension issue.

sure, I understood what you mean, the vid example there the top stitching is so far inside from the edges, it gives the material enough flex to bury the first stitches , the closer the top stitches to the edge then the first stitches get exposed more, especially on part where both sides folded like the edges of collar or gusset or cuff.

if the sleeve is tight and you force your elbow to bend then the stitches is stretched and dig into the hide and get exposed like the inseam of HH's sleeve I guess. happened to some of my jackets since I spec the forearm too ambitiously not really counting the double sided leather on the cuff. it get pulled the first few time I forced zipped my cuff and bend my elbow, it doesn't escalate though once it makes enough room to fit, it would stretch again if I force to wear sweater under my sleeve or if my arm get thicker but it is fine for now poly core thread is quite strong.

visually i think it might look worse on tea core or contrast stitching.

the first jacket I have has the top stitches so close to the edges and not even a hint of the inside stitches, the only answer to me it never stitched from the inside, glueing is also an option. I'm not saying yours is glued, I just said mine was glued on the inside and only top stitched, using glue reduces bulk and thus crisper edge too. I m not saying glue is bad or a cheat my jacket hem is only glued and then cut, not stitched at all and stay like that for 7 years no problem.

Last edited:

jonbuilder

My Mail is Forwarded Here

- Messages

- 3,632

- Location

- Grass Valley CA Foothills

I have tried gloves from a workwear glove company that makes good gloves in deer, goat, and elk. Rated by durability from the best goat - elk - deer. The goat is more pliable than elk and I believe were heaverNot sure what you mean by durability when talking about a jacket, as most of us don't do anything in our jackets that would challenge durability, but i have been beating the crap out if deerskin work gloves for years and they are tough.

They'll get scratched up pretty fast, but the skin itself is super tough, good resistance to puncture, tear, abrasion, all whilst being super soft and allowing good dexterity.

The best bit is that when they get wet they dry soft rather than turning into cardboard.

jonbuilder

My Mail is Forwarded Here

- Messages

- 3,632

- Location

- Grass Valley CA Foothills

The highest tension force my leather jackets have been subject to is when laying my motorcycle down or when a car pulled out in front of me and I bounced off the side of the car. The force pulled the sleeve of my Langlitz at the shoulder seam. I imagine wearing a leather jacket while doing heavy work like construction framing, tieing reinforcing steel, or landscaping will test shoulder and arm seams. In addition to tension forces, abrasion will wear against leather and thread. Ironworkers have favored leather outwear since before I started working in the construction industry, especially welders.I'm no expert in sewing but I do have some experience in bolted connections in steel structures.

When you design or check a steel connection in tension, you take into account, among others, the net area of the steel plate (= cross sectional area of the connecting plate minus the bolt holes - or in our case the sectional area of the leather panel minus the thread holes) and the bearing capacity of the plate (= how the shear force is transferred from the bolt to the plate - in our case how the force is transferred from the thread to the leather).

If the thickness (diameter) of the bolt (or the thread) is the same, and therefore the bolt hole (or thread hole) is the same, then by definition the net area, and thus the overall strength, of the high stitch count is smaller (assuming ofcourse same leather thickness and same leather type).

If we assume that a high stitch count means also smaller thread then the net area can be the same as the net area of a low stitch count panel (= less holes but quite bigger). What we have to check then is the bearing capacity of the panel (or the steel plate).

The bearing capacity is dependent, among others, on the distance p2 between the bolt holes transverse to the tension force; a smaller distance leads to a more problematic transfer of forces and thus to a lower bearing capacity. I attach a fast calculation, where I have assumed that the net area of both a high stitch and low stitch count panel are the same, and indeed the bearing capacity of the high stitch count is lower.

Therefore, from a structural engineering point of view: a higher stitch count leads to lower tensile strength for the panel.

However, some things that have to be taken into account: probably the reduction of the strength is small; even the reduced tensile strength is much higher than any normal tension force that the user will subject his jacket to; maybe for leather the principles of structural mechanics are different than those for steel; or maybe since I still haven't had any coffee I've made some mistakes!

View attachment 299952

Featured products

-

John Lofgren Monkey Boots Shinki Horsebuttt - $1,136 The classic monkey boot silhouette in an incredibly rich Shinki russet horse leather.

John Lofgren Monkey Boots Shinki Horsebuttt - $1,136 The classic monkey boot silhouette in an incredibly rich Shinki russet horse leather. -

Grant Stone Diesel Boot Dark Olive Chromexcel - $395 Goodyear welted, Horween Chromexcel, classic good looks.

Grant Stone Diesel Boot Dark Olive Chromexcel - $395 Goodyear welted, Horween Chromexcel, classic good looks. -

Schott 568 Vandals Jacket - $1,250 The classic Perfecto motorcycle jacket, in a very special limited-edition Schott double rider style.

Schott 568 Vandals Jacket - $1,250 The classic Perfecto motorcycle jacket, in a very special limited-edition Schott double rider style.

jonbuilder

My Mail is Forwarded Here

- Messages

- 3,632

- Location

- Grass Valley CA Foothills

I consider a front drop to be the amount the center of the front hem drops the side and independent of the back of the helm. Mostly I notice a front drop on jackets with shorter backs half belt stylesFront Drop ->

So that is how much longer the front hem of a jacket is than the back hem? Probably a dumb question, just want to be sure.

If this is the case, would a jacket longer in the back have 'back drop?' (Or "Negative Front Drop?")

ps. I can't believe I'm still unclear on this.

Similar threads

- Replies

- 2

- Views

- 477

- Replies

- 18

- Views

- 5K

- Replies

- 3

- Views

- 1K