Rmccamey

I'll Lock Up

- Messages

- 6,061

- Location

- Central Texas

For donor or trial hats, try Facebook market. In Texas, there are always modern cowboy hats for $10, $20, $30 listed right in my neighborhood.

Now you tell me!Sept-Nov is overall the best time to visit Texas. Come back soon.

That's great, Scott (you've probably heard that all your life)!

Really nice, man.

Where did you buy the Nutria hatbody?

Don't tell me you're a trapper too .... please.

Thanks HR Here is the link to the hat bodies.That's great, Scott (you've probably heard that all your life)!

Really nice, man.

Where did you buy the Nutria hatbody?

Don't tell me you're a trapper too .... please.

I like this thread. I dream about figuring out how to make the most durable hat possible.

Yahoody has shown that you can improve the felt of a Winchester body. That's awesome. How "good" can you make it? What were the tricks they used way back when? What corners are cut these days that leave us with poorly felted felt? My mind is ALWAYS in that neck of the woods. I think myself to sleep most nights about just that. Dreaming about coming up with a felt body making process where I could actually make my own body blanks and felt them as good as the hats of long ago. Wouldn't that be nice?

I've bought two custom pure beaver hats from two different makers in my lifetime and neither one could hold up to the elements. I was disappointed in both. Akubra makes outstanding hats out of rabbit, why cant anyone make an even better hat from beaver? I realize it's just a dream but dang is it a fun dream to have. If I ever strike it rich, I'll dedicate my money and time to making that happen!

"I've bought two custom pure beaver hats from two different makers in my lifetime and neither one could hold up to the elements. I was disappointed in both. "

I'm curious how they failed. I wear felt hats almost daily, even in summer, in Texas. I learned decades ago that a hat that would go a couple of years or more and still look good (to me) started at a 20X Resistol or Bailey. I then figured out 100x (100% beaver in Bailey and something less/different in Stetson and Resistol) held up better and then custom 100% beaver did a wee bit better. All got sweat and oil stains that soaked in around the front 1/3 from forehead but the better hats didn't droop from rain and kept shape better. Customs had the best sweatbands. I will say I like my daily wear westerns to be stiff, damned stiff, and the ones that lost stiffness aggravate me since they flop on windy days and when riding fast. I have shallacked several that failed in this way to get them stiff to my liking. I have cleaned and made half-assed attempts at changing them up but mostly settled with stiffening and then shaping them. The stetsons I got years ago always had to be worked on a LOT due to the older (before mid 90's??) westerns always being regular ovals and my head is egg oval. I have only bought one since that time as a result of wanting fit and not wanting to compromise desired shape..

"Many of us watch how the best western felt from 70+ years ago would bend and move. A breeze would cause the entire brim to flip up 90 degrees and then return to shape when the wind stopped."

To any western hat owner I have known known going back now a 100 years, that would be a sub par hat and unusable.

Interesting. I have owned decent felts bought new going back to the 50s, Resistol and Stetson. 7x to 20x. Some of the best felt I have owned is a couple of Bailey 7x hats from the early '90s. That would include my first 100% beaver hat from '93. Still have and wear most of them. But I'd put up the current Winchester beaver bodies again any vintage hat for quality. Much of how a hat feels and is worked depends on the guy's skills and patience that working on the felt body.

When I am too busy or just too lazy to build myself a new hat I have a couple of custom hatters I go to. There are store bought hats I could get cheaper, then reblock and reshape to my liking. Tempted to do so about once a week generally. But then I remember just how bad the junk felt that any $500 or less store bought hat uses. (Akubra being the exception as posted prior and Amish fur felt) and I cringe. Just no interest in bad felt.

I've seen some mighty pitiful 100% beaver come from Winchester in two instances in the last 10 years. Looking back..as I still have both...likely dress weight bodies passed off as western bodies by either Winchester or the hat maker. Way too soft for my use either way.

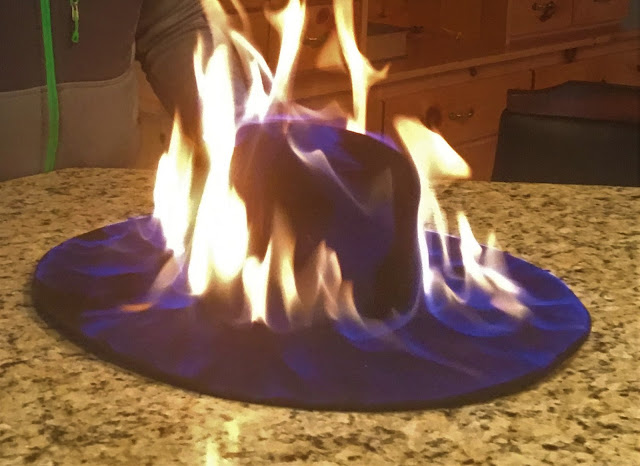

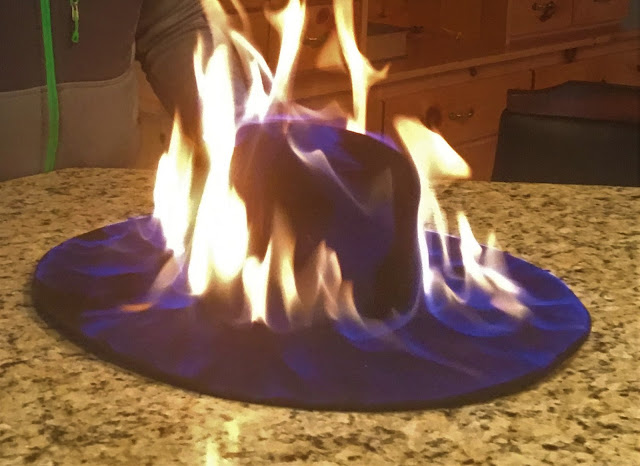

Not being able to "change" a felt blank? Ya, I have to disagree with that to some extent. Dress weight felt isn't western grade felt for sure. But an unfired western felt isn't going to be much better than dress felt till it is fired properly. If you know what you are doing, firing a 100% beaver blank makes all the difference in the world in what you get for a durable hat, be it in the rain or how stiff the brim is and will stay over time. Firing the felt interlocks the fur fibers tighter in the felt than how they come from the felter. A lot tighter. It is how you get a durable and stiff hat with no shellac. I don't use shellac on any of my own hats. But have used cans of it on a couple of sub par 100% beaver hat blanks from Winchester that other hatters have built on.

I'd consider any western felt hat, of any brim size, that bent in the wind on a loping horse a POS hat. Simply would not wear it.

Still pretty dusty here and will be for another month or two. But tomorrow I'll do a before and after photo when I brush off and clean up that black hat some. Should be able to give you an idea just how stiff a good hat body can be compared to one that aint.

That hat has been soaked through with rain more times than I can remember. I don't rebuild or re-block it, just let it dry in our front room typically in the mid 70s and the low humidity of our climate.

John Lofgren Monkey Boots Shinki Horsebuttt - $1,136 The classic monkey boot silhouette in an incredibly rich Shinki russet horse leather.

John Lofgren Monkey Boots Shinki Horsebuttt - $1,136 The classic monkey boot silhouette in an incredibly rich Shinki russet horse leather.  Grant Stone Diesel Boot Dark Olive Chromexcel - $395 Goodyear welted, Horween Chromexcel, classic good looks.

Grant Stone Diesel Boot Dark Olive Chromexcel - $395 Goodyear welted, Horween Chromexcel, classic good looks.  Schott 568 Vandals Jacket - $1,250 The classic Perfecto motorcycle jacket, in a very special limited-edition Schott double rider style.

Schott 568 Vandals Jacket - $1,250 The classic Perfecto motorcycle jacket, in a very special limited-edition Schott double rider style. "the hats of all the movie cowboys from the pre-War period were much softer than the felt we see today. The hats used by cavalrymen were much softer than the hats we have today. The hats worked out for those users."

We'll have to agree to disagree. If I wanted a softer hat like you describe I'd get a dress felt to start with. Been there done that. The original turn of the century and earlier cavalry hats were trash. Typical government issue clothing for the day...trash. "Worked out" is relative I suspect to your expectations.

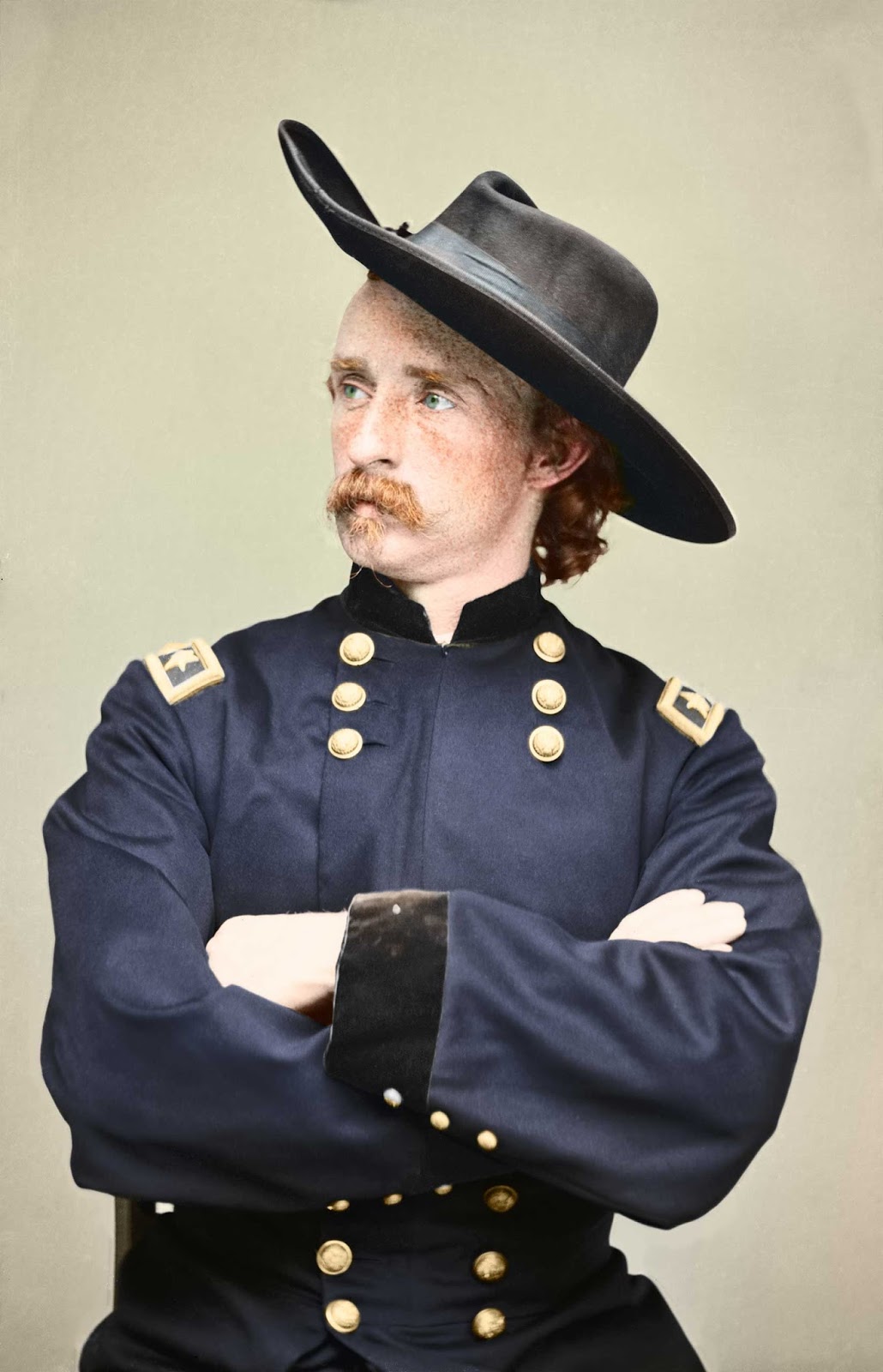

Also why many of Custer's crew used straw hats on the summer campaigns. Straw held up better than the issue felts even if it did bend in the wind on a horse. During the Civil War?

"In early June 1863 Custer, assigned to a cavalry unit, showed particular bravery when confronting a Confederate force near Aldie, Virginia. Wearing a wide-brimmed straw hat, Custer led a cavalry charge that put him, at one point, in the midst of the Confederate force. Legend has it that the enemy, seeing Custer's distinctive hat, took him for one of their own, and in the confusion he was able to spur his horse and escape."

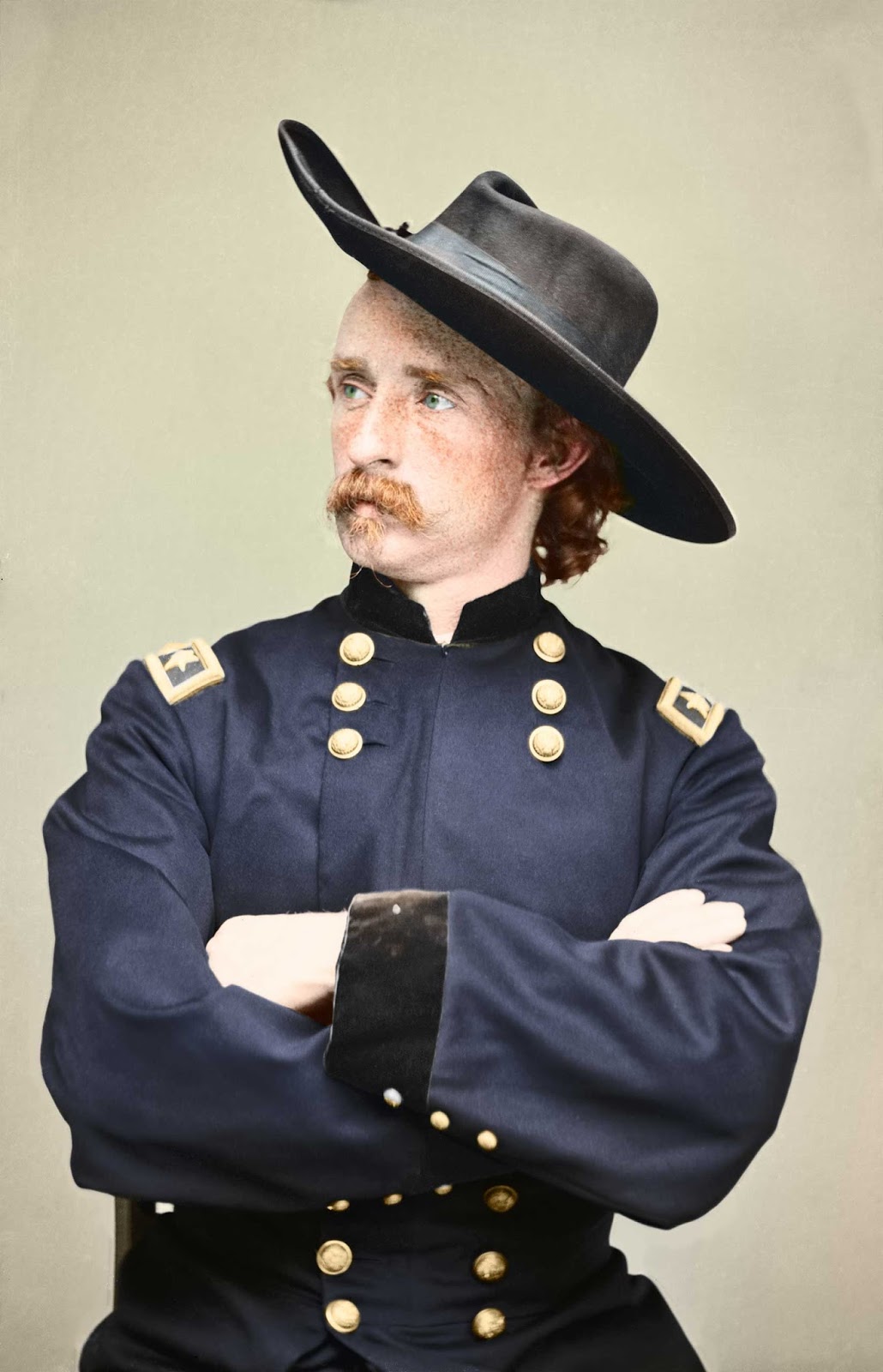

Custer

civil war era hats

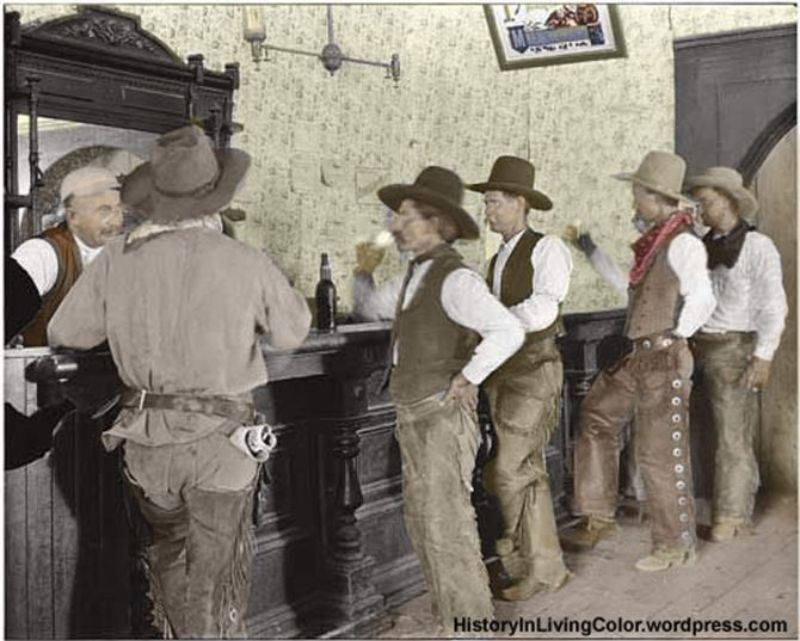

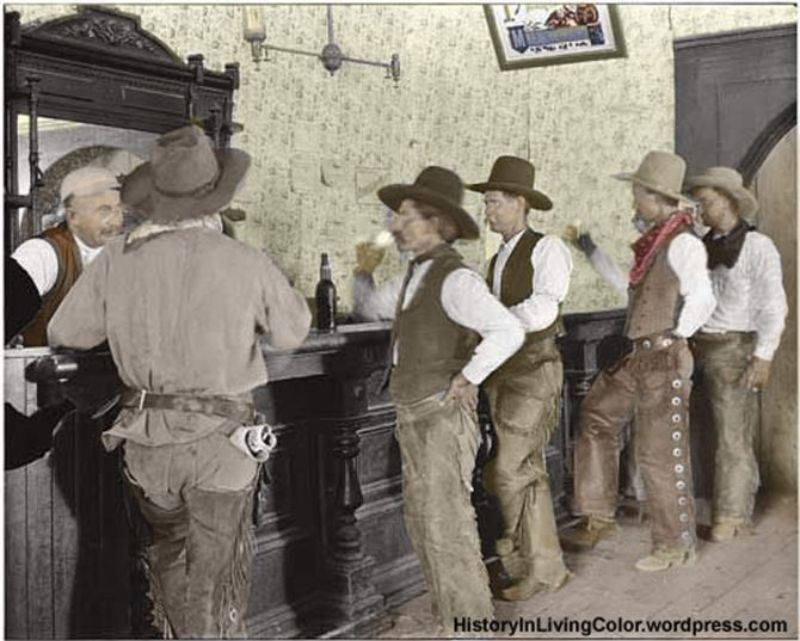

early 1880s likely by the new #3 pictured

1901 Montana. By 1900 a "good" felt cowboy hat used bound edges and pencil rolls on the big brimmed hats to stiffen the brims just to avoid a bent brim. Small brims on a good felt hat by the '20s didn't need either. Pretty obvious what a new hat looked like compared to an older and well used one in this photo.

early '50s in South Dakota

I bought a pure white 10X beaver Bailey western on Ebay a while back. I dyed it grey in very hot water, just off the boil. The felt was good quality, dense and stiff. During the dying process the hat refelted or conintued to felt. The body came out much much smaller and waaaay more dense. I call it my bullet proof hat as I am convinced it is kevlar like and could shed a bullet. Do you think this dyeing process and the re-felting made the hat more impervious to rain and in any way improved the quality of the felt? It came out in the end with the same level of stiffness.Interesting. I have owned decent felts bought new going back to the 50s, Resistol and Stetson. 7x to 20x. Some of the best felt I have owned is a couple of Bailey 7x hats from the early '90s. That would include my first 100% beaver hat from '93. Still have and wear most of them. But I'd put up the current Winchester beaver bodies again any vintage hat for quality. Much of how a hat feels and is worked depends on the guy's skills and patience that working on the felt body.

When I am too busy or just too lazy to build myself a new hat I have a couple of custom hatters I go to. There are store bought hats I could get cheaper, then reblock and reshape to my liking. Tempted to do so about once a week generally. But then I remember just how bad the junk felt that any $500 or less store bought hat uses. (Akubra being the exception as posted prior and Amish fur felt) and I cringe. Just no interest in bad felt.

I've seen some mighty pitiful 100% beaver come from Winchester in two instances in the last 10 years. Looking back..as I still have both...likely dress weight bodies passed off as western bodies by either Winchester or the hat maker. Way too soft for my use either way.

Not being able to "change" a felt blank? Ya, I have to disagree with that to some extent. Dress weight felt isn't western grade felt for sure. But an unfired western felt isn't going to be much better than dress felt till it is fired properly. If you know what you are doing, firing a 100% beaver blank makes all the difference in the world in what you get for a durable hat, be it in the rain or how stiff the brim is and will stay over time. Firing the felt interlocks the fur fibers tighter in the felt than how they come from the felter. A lot tighter. It is how you get a durable and stiff hat with no shellac. I don't use shellac on any of my own hats. But have used cans of it on a couple of sub par 100% beaver hat blanks from Winchester that other hatters have built on.

I'd consider any western felt hat, of any brim size, that bent in the wind on a loping horse a POS hat. Simply would not wear it.

Still pretty dusty here and will be for another month or two. But tomorrow I'll do a before and after photo when I brush off and clean up that black hat some. Should be able to give you an idea just how stiff a good hat body can be compared to one that aint.

That hat has been soaked through with rain more times than I can remember. I don't rebuild or re-block it, just let it dry in our front room typically in the mid 70s and the low humidity of our climate.

"I've bought two custom pure beaver hats from two different makers in my lifetime and neither one could hold up to the elements. I was disappointed in both. "

I'm curious how they failed. I wear felt hats almost daily, even in summer, in Texas. I learned decades ago that a hat that would go a couple of years or more and still look good (to me) started at a 20X Resistol or Bailey. I then figured out 100x (100% beaver in Bailey and something less/different in Stetson and Resistol) held up better and then custom 100% beaver did a wee bit better. All got sweat and oil stains that soaked in around the front 1/3 from forehead but the better hats didn't droop from rain and kept shape better. Customs had the best sweatbands. I will say I like my daily wear westerns to be stiff, damned stiff, and the ones that lost stiffness aggravate me since they flop on windy days and when riding fast. I have shallacked several that failed in this way to get them stiff to my liking. I have cleaned and made half-assed attempts at changing them up but mostly settled with stiffening and then shaping them. The stetsons I got years ago always had to be worked on a LOT due to the older (before mid 90's??) westerns always being regular ovals and my head is egg oval. I have only bought one since that time as a result of wanting fit and not wanting to compromise desired shape..