Guttersnipe

One Too Many

- Messages

- 1,942

- Location

- San Francisco, CA

Dacron:

One of the names the Du Pont Company uses for a polymer fiber—polyethylene terephthalate--that John Rex Whinfield (1901-1966) and J. T. Dickinson developed in Great Britain in 1941. Whinfield and Dickinson called their new synthetic fiber Terylene.

At the time that Whinfield and Dickinson were working on Terylene, the race to develop substitutes for natural fibers was on. Nylon, invented by Wallace Hume Carothers (1896-1937), an American chemist at Du Pont, had been doing a booming business since its introduction in 1935. Rayon, invented in 1892, was another synthetic fiber in high demand. Any similar product stood a good chance of being successful.

Despite intensive research at Du Pont, Carothers had found the fibers of most polyesters unsuitable for use in textiles because of their low melting temperatures. One reaction Carothers and his team had not tried was the one Whinfield and Dickinson used to create polyethylene terephthalate--that is, reacting ethylene glycol with terephthalic acid to produce long polymer chains.

Dacron fibers are made by heating the polymer and forcing it through a metal plate with small holes. The fibers are drawn out and passed through a pair of rollers rotating at different speeds. This orients the molecules into long linear chains and allows cross-linking to occur. Cross-linking connects the linear chains to each other, forming a three-dimensional network that strengthens the macromolecules. The high melting temperature of polyethylene terephthalate, 496 degrees Fahrenheit (256 degrees Celsius), is due to this cross-linking. The discovery of Dacron revolutionized the textile industry. As one of the first artificial fibers, it could be used both in wool blends or by itself. Hundreds of tons of Dacron are produced each year.

And although originally desired as a textile fiber, polyethylene terephthalate is now used in film and tape (virtually all magnetic recording tape is based on this material), as a molding material, and as the matrix for glass-filled composites. One its largest uses is in bottles, especially soda pop bottles. It is also used in blends with other polymers, such as polycarbonate.

Recycling of polyethylene terephthalate can be accomplished by chemical depolymerization to polyethylene terephthalate and other products. Such processes are currently in use for products that come in contact with food.

Citation

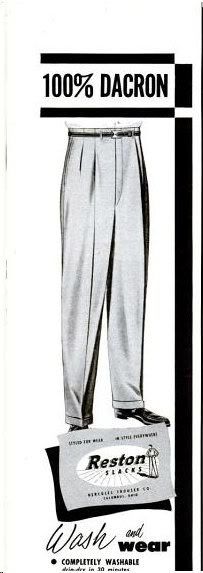

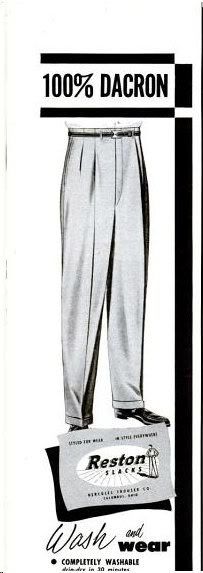

Here's a scan of a magazine ad from 1957:

One of the names the Du Pont Company uses for a polymer fiber—polyethylene terephthalate--that John Rex Whinfield (1901-1966) and J. T. Dickinson developed in Great Britain in 1941. Whinfield and Dickinson called their new synthetic fiber Terylene.

At the time that Whinfield and Dickinson were working on Terylene, the race to develop substitutes for natural fibers was on. Nylon, invented by Wallace Hume Carothers (1896-1937), an American chemist at Du Pont, had been doing a booming business since its introduction in 1935. Rayon, invented in 1892, was another synthetic fiber in high demand. Any similar product stood a good chance of being successful.

Despite intensive research at Du Pont, Carothers had found the fibers of most polyesters unsuitable for use in textiles because of their low melting temperatures. One reaction Carothers and his team had not tried was the one Whinfield and Dickinson used to create polyethylene terephthalate--that is, reacting ethylene glycol with terephthalic acid to produce long polymer chains.

Dacron fibers are made by heating the polymer and forcing it through a metal plate with small holes. The fibers are drawn out and passed through a pair of rollers rotating at different speeds. This orients the molecules into long linear chains and allows cross-linking to occur. Cross-linking connects the linear chains to each other, forming a three-dimensional network that strengthens the macromolecules. The high melting temperature of polyethylene terephthalate, 496 degrees Fahrenheit (256 degrees Celsius), is due to this cross-linking. The discovery of Dacron revolutionized the textile industry. As one of the first artificial fibers, it could be used both in wool blends or by itself. Hundreds of tons of Dacron are produced each year.

And although originally desired as a textile fiber, polyethylene terephthalate is now used in film and tape (virtually all magnetic recording tape is based on this material), as a molding material, and as the matrix for glass-filled composites. One its largest uses is in bottles, especially soda pop bottles. It is also used in blends with other polymers, such as polycarbonate.

Recycling of polyethylene terephthalate can be accomplished by chemical depolymerization to polyethylene terephthalate and other products. Such processes are currently in use for products that come in contact with food.

Citation

Here's a scan of a magazine ad from 1957: